A world leader in steel corrugated storage bin manufacturing, GSI offers the strongest and heaviest gauge storage tanks in the industry with capacities up to 1.1 million bushels. Our tank sidewall is roll-formed at the GSI plant using 8 gauge, and now 5 and 6 gauge, prime high tensile steel up to 70,000 PSI (483 MPa). The heavier 5 gauge sidewall allows us to provide taller tanks with our advanced design, compared to other manufacturers who provide 8 gauge as their maximum thickness.

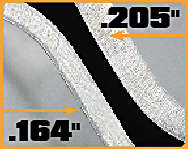

8 Gauge vs. 5 Gauge Galvanized Steel

The heaviest galvanized steel previously available for sidewall panels was 8 gauge (.164”). GSI’s exclusive 5 gauge (.205”) galvanized steel sidewall panels however are 25% thicker and provide up to a 37.5% increase in overall strength.

Combined with a “quad” punching pattern in the vertical bolt seams of the sidewall to assure a strong connection between panels and a commercial galvanized coating to provide the utmost durability, the result is a commercial galvanized steel tank unmatched throughout the industry in overall strength and reliability.

In addition, the Million Bushel Bin uses a new, high strength, six bolt connection pattern.

70,000 PSI High-Strength Stiffener Columns

Tank strength is further maximized through the use of GSI’s strong upright stiffener columns which carry the vertical load of the bin to the foundation. Manufactured from high strength 70,000 PSI (483 MPa) steel, GSI’s stiffeners feature strong splice joints with large cross sectional areas, both critical elements of vertical stiffeners. Stiffeners are galvanized and mounted either internally or externally based on your requirements.

Easy Access Sidewall Door

A standard 24” diameter round access door is located in the second ring of all GSI commercial tanks (up to 105’ diameter). GSI also offers an optional two ring door (standard on 135’ diameter bins) that provides superior access for entering and exiting the bin. The commercial two ring doors features strong frames around the opening and an easy opening two piece inner panel design.

GSI also offers an optional vehicle traffic door for use in situations where skid-steer loaders will be used for final clean out, or even larger openings are required.

Zinc Plated Bolts

Heavy zinc plated, high strength, dichromate coated bolts up to grade No. 8 are used on all GSI bins. Each bolt has a special sealing washer for an unbeatable weather seal.

Solid “Wide Flange” Roof Support

GSI commercial tanks feature an exceptionally strong structural roof support system. Structural “wide flange” steel beams are the backbone for GSI roofs on larger diameter tanks yielding peak loads of up to 25,000 pounds. This structural beam design also allows quick and simple roof construction. Even the smaller diameter bins (42 ft. – 60 ft.) feature galvanized rafter systems spanning from eave to peak for extra solid roof support.

Heavy Roof Peak “Flat Top”

The GSI “Flat Top” is a structurally welded, flat platform providing a large surface to attach overhead equipment, spouting, catwalks, etc. without the costly field fabrication. The “Flat Top” comes standard on all 54 ft. dia. and larger tanks (optional on 33 ft. – 48 ft.) and requires no time consuming field assembly.

High Tensile/Fully Overlapping Roof Panels

GSI bin roof ribs are taller, fully double lapped and have four extra reinforcing ledges. The roof ribs, together with corrugated panels and 55,000 PSI high tensile steel, combine to form an exceptionally strong and reliable roof panel system. Each roof panel is manufactured using GSI’s exclusive, fully automated, roll forming line. This insures a precise and consistent fit throughout assembly and helps maintain a tight steel to steel seal between panels. Only GSI offers this level of accuracy in roof panel manufacturing.

Roof Support Ring

This optional feature provides a ring between the peak fill hole and the eave. Die formed brackets firmly secure the ring to the roof ribs, and provide additional roof strength as well.

Roof Vents for Increased Efficiency

GSI manufactures two very unique vents to fit your particular requirements. The hinged grill vent features a vertically mounted, large mesh, wire formed screen to keep out pests and swings freely open to allow easy release of trash buildup. The Auto-Vent is a revolutionary concept in vent design reducing “plugging” or air restriction. When fans are running, air passes freely above and below a wing-shaped damper allowing it to float open in mid air. The damper drops down and closes when the fan is not in operation, also helping to block wind, snow, birds, etc. from entering. Both vents are assembled with a heavy duty lock seam for added strength. Prepunched, extruded lip roof panels and a special die-cut gasket help provide a weather tight connection between the vent and roof panel. GSI also manufactures a power roof exhauster for situations requiring greater airflow. These are available in a 24” diameter, 2 HP model and an 18” diameter, 1/2 HP model.

Safety Cages and Platforms

GSI safety cages are completely galvanized and bolt directly to the prepunched sidewall ladders. The bottom of the cage has a bell section which allows ample space while ascending and descending the ladder. A platform can also be constructed below the manhole for your convenience when entering, exiting or inspecting the roof. The platform is die formed from galvanized steel, and has a specially designed floor for slip resistance.

Sidewall Ladders

Each bin can be ordered with a sturdy sidewall ladder for easy access. Each ladder section is made from roll-formed side rails with press fit dimped rungs. Ladder sections are attached to the bin wall with compression type connectors to allow for easy assembly and adjustment. Ladders are available in 48′, 36′ or 24′ sections.

Custom Floor Designs

Many aeration floor systems are available from full floors above concrete with custom plenum heights, to various flush floor in-concrete patterns. Grain Systems can also provide hopper bottom aeration systems for concrete hopper foundations or steel commercial hopper bottomed tanks. MORE