The GSI Modular Tower Dryer Series uses modular construction to improve overall fit, dependability and speed of installation. Building on site, often referred to as “Stick Built” has been the standard method of construction for the larger tower dryers that the GSI Group manufactures. However, with Modular Tower Dryer comes the option to factory assemble a tower dryer in sections, then ship the dryer to the site for final assembly.

This leads to several improvements, including:

• Assembly at the GSI’s state of the art manufacturing plant means labor time on site is reduced and labor efficiency can be maximized.

• The use of specially built jigs ensures that each module is exactly right, ready to fasten to the other modules with a minimum of adjustment or work.

• Shipping in modules means fewer part backorders due to limited availability or damage to parts in transit.

• On site assembly can be done quickly with a crane with almost all work occurring close to the ground.

• The modular design allows for a standard adjustable unload auger that extends past the outside edge of the dryer with a clearance of 8″ to 42”, with the option to direct discharge at the center of the dryer with 24″ of clearance.

• Safety and operational devices are pre-installed on each module. Wire and conduit are ready to uncoil and wire to the main control boxes reducing time and chance of error.

• Control boxes, though remote install capable, are mounted on the base module ready to accept the wiring from the other modules.

• Controls are pre-powered and all module wiring and components pre-tested to assure correct operation and improved dependability at startup.

• Modular construction makes relocating the dryer easier. Download Modular Tower Dryer Animation

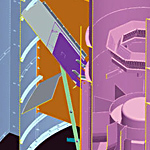

Adjustable Cooling Floor

GSI Modular Dryers have a unique and patented pending feature called the Adjustable Cooling Floor. This floor allows two major improvements to the dryers operation.

In the past, Tower dryers were designed for a 67/33 split with its traditional Dry and Cool ability, or the 80/20 split with its ability to achieve greater capacities in grain over 25% or operate in partial cooling mode. It is now possible to have both with the GSI Modular Dryer adjustable cooling feature. This feature involves 8 hinged doors that can change the split from approximately 67/33 to 80/20 and back again in a matter of minutes. Each door can be locked in either position by individual control handles easily reached from the service area in the cooling section of the dryer.

If the harvest year starts at 30%, the modular dryer can operate in the minimum cooling position delivering dried and cooled grain within 10 degrees of the ambient temperature. For grain nearing 20%, the modular dryer doors can be adjusted to the maximum cooling position for optimum grain drying and cooling results. Used in combination with adequate cooling air in cooling bins, the modular dryer doors can be adjusted to the minimum cooling position to take advantage of additional capacity. Only the GSI Modular Tower Dryer allows this simple method for controlling the amount of cooling that is to be applied.

In addition, the Modular Tower Dryer features a self cleaning design. Specially designed divider floors allow any chaff or fines that would otherwise accumulate in the heat chamber to drop into the cooling chamber. The Adjustable Cooling Floor prevents particulate build up in the heat plenum of the dryer in the minimum or maximum cooling positions.

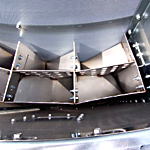

Patented All Stainless Steel Grain Inverters

Inverters promote more even drying, higher test weights, and help reduce operating costs.

While the older grain exchangers move grain from the inside of the grain column to the outside of the column in 6” columns, the patented GSI Grain Inverters put a new twist on this process.

GSI’s Grain Inverters move all grain, except the outer two inches, within the column to eliminate over-dried grain and to maximize drying efficiency and grain quality. These patented Grain Inverters place the warmest grain from the inside of the column next to the wettest grain at the outside of the column. The wet grain at the outer wall is dried by the captured heat which would have otherwise escaped the dryer.

This process maintains optimal grain temperature, thus maximizing grain quality while using less fuel and significantly reducing operating costs. A convenient clean-out door also provides easy access for quick maintenance.

Vision Dryer Controls

The GSI Vision dryer control system features a wide array of settings that offers unparalleled options and control. Boasting a 10.4″ TFT color touch screen with easy-to-use controls, the Vision can be remote-mounted, via a simple seven wire harness, up to 1000 feet away from the dryer.

The Vision system features a low voltage safety circuit and a safety disconnect on every dryer. Each safety is monitored individually and its status displayed on-screen. With no moving parts – timers, time delays, thermostats, etc. – the Vision system is less prone to wear-and-tear that leads to costly repairs and downtime. Plenum and grain temperatures can be modified on-screen. You can also change from High/Low to On/Off fire mode which allows plenum operation down to 5 degrees above ambient with a simple software switch. MORE