T-Series Tower Dryers are designed with the mid-sized to large farm in mind. Capacities range from 1000 BPH to 2400 BPH. All heat from cooling the grain is recycled and the long retention times result in very efficient dryer operation. A divider hopper prevents the build-up of fines in the heat section, simplifying maintenance.

Self diagnostic controls accurately monitor grain moisture and temperature. If you need an efficient, quiet, and dependable drying system, the GSI T-Series Tower Dryer is just what you’re looking for.

Mixed Flow Industrial Blower

Highly efficient, quiet industrial blower used on all T-Series dryers, provides years of trouble free operation.

MAXON NP-LE-AL Burner

For 1500 BPH and larger capacities. Maxon fuel efficient, low nox in-line burner, with engineered profiling provides even continuous heat. Aluminum extrusion reduces burner maintenance.

Inner Roof

Heavy galvanized inner roof and support provides over 300 bushels of wet holding in the garner. The garner is totally sealed to retain particulate matter.

Platforms

Inside/outside platforms, ladders and cages are standard and provide access to the dryer.

Access Doors and Hatches

All areas of the dryer are accessible through doors and floor hatches for easy cleaning and maintenance.

Metering Drive

The SCR variable speed DC motor and the single maintenance free Cyclo gearbox located in the cooling chamber provides simple, trouble free operation of the dryers metering system.

Sweep Discharge

Field proven (patented) Accu-trol Metering System is self cleaning and provides positive grain flow.

Heat Plenum Chamber

The heat plenum chamber is entirely surrounded by a 12.75″ grain column. All heated air must pass through the grain column resulting in total use of heated air. Stainless steel, smooth sidewall construction with .078″ and .0625″ perforation diameter helps retain particulate matter.

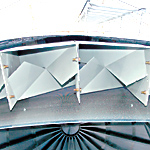

Patented Grain Inverters

Promote more even drying, higher test weights, and also help reduce operating costs.

While the older grain exchangers move grain from the inside of the grain column to the outside of the column in 6” columns, the patented GSI Grain Inverters put a new twist on this process.

GSI’s Grain Inverters move all grain, except the outer two inches, within the column to eliminate over-dried grain and to maximize drying efficiency and grain quality. These patented Grain Inverters redirect the warmest grain from the inside of the column to be next to the wettest grain left at the outside of the column where it is dried by the captured heat which would have otherwise escaped the dryer. (See diagram to below for visual illustration)

This process maintains optimal grain temperature, thus maximizing grain quality while using less fuel and significantly reducing operating costs.

A convenient clean-out door also provides easy access for quick maintenance.

Kernel Temperature

Under 100° = Seed

100° to 120° = Human Food Grade – Full Nutrition and Taste

120° to 140° = Animal Food Grade – Full Nutrition

140° to 160° = Moderate Damage and Test Weight Loss Starts

160° and above = Severe Damage (Physical Breakage and Severe Test Weight Loss)

Vision Dryer Controls

The GSI Vision dryer control system features a wide array of settings that offers unparalleled options and control. Boasting a 10.4″ TFT color touch screen with easy-to-use controls, the Vision can be remote-mounted, via a simple seven wire harness, up to 1000 feet away from the dryer.

Because safety and dependability are paramount for all GSI products, the Vision system features a low voltage safety circuit and a safety disconnect on every dryer. Each safety is monitored individually and its status displayed on-screen. With no moving parts – timers, time delays, thermostats, etc. – the Vision system is less prone to wear-and-tear that leads to costly repairs and downtime. Plenum and grain temperatures can be modified on-screen. You can also change from High/Low to On/Off fire mode which allows plenum operation down to 5 degrees above ambient with a simple software switch. MORE