GSI has a reputation for engineering excellence. The tower dryer exemplifies this, with design innovations unmatched by anyone in the industry.

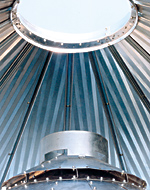

The tower dryer design utilizes industry proven drying principles along with many unique features to provide the commercial user with a simple, reliable, fuel efficient grain dryer. Each dryer employs a bolt together (versus welded) design, which permits the wide use of galvanized steel (versus painted steel) throughout the dryer. In addition, all dryers have stainless steel, roll formed exterior sheeting as a standard feature. These design features simplify dryer erection, improve dryer appearance and promote a long dryer life.

The hopper bottom design used on the dryer, including GSI’s patented metering drum, provides a simple and efficient grain discharge system. This system transfers grain from the dryer uniformly and allows for easy dryer clean-out. Touch screen controls offer computerized control of all dryer functions. This “smart” system eliminates the guesswork by providing the operator instant information on a large backlit color display and simplifies the operation of the dryer.

Superior Workmanship

Standard operational features on the dryer include double Maxon gas blocking valves on the gas train, exhaust air temperature sensors, plenum high temperature limits, grain level monitoring, continuous flame monitoring, airflow monitoring and motor overload monitoring. We take pride in the design and workmanship that goes into the tower dryer, and stand behind it with a one full year parts and labor warranty.

Customer Service

Should you ever need service on your GSI tower dryer, we have a professional staff of service technicians who can take care of your service needs.

Efficient Design

Grain enters the dryer at the top and falls into a self cleaning grain receiving chamber. The chamber creates a grain cushion, and with grain falling on grain, helps reduce plenum roof wear. This chamber also provides a means of distributing grain evenly around the dryer. The garner bin at the top of the dryer has a full 40 inches of wet grain storage. This area is completely sealed to help retain grain dust and particulates.

Grain moves down, out of the garner area, and enters 12” wide grain drying columns in the heat section of the dryer. The tower dryer is designed to provide the optimum balance of grain retention time, airflow and temperature. Large column holding capacities result in long grain retention times in the drying section of the dryer. This long retention time, combined with low drying airflows and temperatures result in high quality, efficiently dried grain.

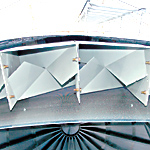

Midway down the heat section of the dryer are GSI’s patented grain inverters. The inverters invert the grain from the inside of the grain column to the outside for more uniformly dried grain.

GSI tower dryers are designed to retain bees wings and particulate matter within the drying columns. The largest standard hole size on the exterior screening of the dryer is 0.078 inch diameter perforation. After the grain is turned, the perforation size drops to a diameter of 0.0625 inches. Solid non-perforated exterior sheets are used at the grain inverters and at the top and bottom of the grain columns to help ensure that particulates are not expelled from the dryer.

As grain exits the heat section of the dryer it enters the suction cooling section. Air used to cool the grain is recycled through the blower(s) resulting in significant energy savings.

Blowers and Burners

Depending on the size of the dryer, one, three, or four industrial duty blowers are used in the tower dryer. These internally mounted, in-line mixed flow blowers are sized to operate at slow speeds, which means low noise levels, low electrical usage and long blower and motor life.

Airflow from the blowers is ducted across a Maxon NP-LE-AL line burner. The burner can operate on either natural gas or LP vapor. The burners are sized and profiled to provide even, efficient heat distribution to the drying section of the dryer. (fuel oil burners are optional)

Discharge Area

Cool, dried grain passes from the cooling section of the dryer into the sealed, hoppered discharge section. Grain is gravity fed down a 45° hopper to GSI’s patented metering drum. This drum provides a positive, yet gentle means of metering grain uniformly from each column of the dryer and discharging it out the center of the dryer. The drum is driven by a variable speed inverter operated AC motor. The hopper bottom design of the dryer eliminates troublesome sweep augers and sweep arms and provides for quick dryer clean-out.

Patented Grain Inverters

Patented Grain Inverters promote more even drying, higher test weights, and also help reduce operating costs.

While the older grain exchangers move grain from the inside of the grain column to the outside of the column in 6” columns, the patented GSI Grain Inverters put a new twist on this process.

GSI’s Grain Inverters move all grain, except the outer two inches, within the column to eliminate over-dried grain and to maximize drying efficiency and grain quality. These patented Grain Inverters redirect the warmest grain from the inside of the column next to the wettest grain left at the outside of the column. The wet grain at the outer wall is dried by the captured heat which would have otherwise escaped the dryer. (See diagrams below for visual illustration) This process maintains optimal grain temperature, thus maximizing grain quality while using less fuel and significantly reducing operating costs.

A convenient clean-out door also provides easy access for quick maintenance.

Kernel Temperature

Under 100° = Seed

100° to 120° = Human Food Grade – Full Nutrition and Taste

120° to 140° = Animal Food Grade – Full Nutrition

140° to 160° = Moderate Damage and Test Weight Loss Starts

160° and above = Severe Damage (Physical Breakage and Severe Test Weight Loss)

Touch Screen Control Panel

GSI’s touch screen control panel is the most advanced and reliable dryer control system on the market. It offers computerized control of all dryer functions and self diagnoses dryer problems eliminating the guesswork associated with traditional controllers. The touch screen is very simple to operate providing instant information via a large color display. It calculates total dryer time, bushels per hour and total bushels dried. Memory features in the unit maintain a history of past dryer operation and a permanent service record.

Control Box

The control box is housed in a metal NEMA IV enclosure. The windowed design of the box allows all dryer operations to be viewed through the lockable windowed door and also protects all control switches, indicators, and controls. For convenience, the control box can be remote mounted or mounted at the dryer. The touch screen control panel, pictured at the left, is totally computerized using Allen Bradley industrial controls and communicates with the dryer power box via an DH485 communication link.

The dryer power box is mounted in a large NEMA IV enclosure, all of the electrical power and dryer monitoring components for the dryer are controlled by an Allen Bradley SLC controller. The electrical layout and wiring of this box is MET laboratories certified, making the box meet all U.S. and Canadian safety standards. This will provide a long reliable control system for the dryer.

The electronic control panel indicates any malfunctions via a full color graphical display. The display provides continuous visual feedback on the current dryer status as well as a convenient means of setting operating parameters and options. Most set points and status screens are accessed by simply touching an on-screen object. This clear and simple control system saves valuable time in dryer operation and the area of troubleshooting.

Heat Plenum Chamber

The heat plenum chamber is entirely surrounded by a 12.75″ grain column. All heated air must pass through the grain column resulting in total use of heated air. Stainless steel, smooth sidewall construction with .078″ and .0625″ perforation diameter helps retain particulate matter.

Inside:

- Heating section has .078″ perforation sidewalls.

- Cooling section has .0625″ perforation to minimize particulate matter entering the cooling section.

Outside:

- Heating section to the Grain Inverter has .078″ perforation sidewalls.

- Grain Inverter to the cooling section has .0625″ perforation sidewalls to contain the particulate matter.

- Cooling section has .078″ perforation sidewalls.

Easy Access

The tower dryer was designed with convenience in mind. Catwalks, ladders and cages are provided on all areas of the dryer for easy accessibility. All areas of the dryer can be easily accessed through up to four entry ways. Cleanout, inspection, and general maintenance are never a problem.

Heavy-duty materials and strong structural design provide a solid support for ladders and platforms.